Industry Insights: Relative Humidity & Wood

May 1, 2021

Hardwood has long been the top choice for floor surfaces in a home and it is easy to understand why with its warm, welcoming nature and stunning beauty. Whether you are looking to build a new home or remodel, adding hardwood floors is not just an aesthetically appealing choice but an investment that will last you many decades to come. But your hardwood floor will only turn heads if it is correctly installed and maintained. One of the largest factors in whether or not your hardwood floor will function as intended and last is its relationship with humidity before, during, and after installation.

Equilibrium Moisture Content (EMC)

Wood is hygroscopic material. Simply put, when wood is exposed to air it will gain or lose moisture until it is at equilibrium with the humidity and temperature in the air surrounding it. This is an ongoing balancing act as the humidity and temperature will change from season to season. Summer months will have high humidity and temperatures while winter months will be lower.

When the wood has reached a point at which it no longer absorbs or expels moisture it is considered to have reached an equilibrium moisture content (EMC).

Equilibrium Moisture Content (EMC)

Wood is hygroscopic material. Simply put, when wood is exposed to air it will gain or lose moisture until it is at equilibrium with the humidity and temperature in the air surrounding it. This is an ongoing balancing act as the humidity and temperature will change from season to season. Summer months will have high humidity and temperatures while winter months will be lower.

When the wood has reached a point at which it no longer absorbs or expels moisture it is considered to have reached an equilibrium moisture content (EMC).

Movement occurs across the face of the grain.

Moisture's Effect On Wood

Generally speaking, wood flooring can be expected to shrink in dry environments (low humidity) and expand in wetter environments (high humidity).

When wood undergoes expansion or contraction it will do so perpendicular to the direction of the grain. Wider boards tend to move more than narrower boards. Movement in a 5in wide plank is more dramatic than in a 2-1/4in plank.

Engineered floors undergo far less expansion and contraction with moisture changes.

Let’s say a width variation is just 1/16inch for a 2-1/4″ board. That would mean a movement of 1inch over 3ft. Over the width of a 12 foot wide room that is a 4in of total expansion or contraction.

Movement will not occur the direction of the grain

Moisture's Effect On Wood

Generally speaking, wood flooring can be expected to shrink in dry environments (low humidity) and expand in wetter environments (high humidity).

When wood undergoes expansion or contraction it will do so perpendicular to the direction of the grain. Wider boards tend to move more than narrower boards. Movement in a 5in wide plank is more dramatic than in a 2-1/4in plank.

Engineered floors undergo far less expansion and contraction with moisture changes.

Let’s say a width variation is just 1/16inch for a 2-1/4″ board. That would mean a movement of 1inch over 3ft. Over the width of a 12 foot wide room that is a 4in of total expansion or contraction.

Movement occurs across the face of the grain.

Movement will not occur the direction of the grain

Moisture's Effect On Wood

Generally speaking, wood flooring can be expected to shrink in dry environments (low humidity) and expand in wetter environments (high humidity).

When wood undergoes expansion or contraction it will do so perpendicular to the direction of the grain. Wider boards tend to move more than narrower boards. Movement in a 5in wide plank is more dramatic than in a 2-1/4in plank.

Engineered floors undergo far less expansion and contraction with moisture changes.

Let’s say a width variation is just 1/16inch for a 2-1/4″ board. That would mean a movement of 1inch over 3ft. Over the width of a 12 foot wide room that is a 4in of total expansion or contraction.

Movement occurs across the face of the grain.

Movement will not occur the direction of the grain

Ideal Moisture Content for Hardwood Floors

The ideal moisture content for hardwood floors can vary depending upon wood species, geographic location, and the seasonal time of year. For instance, the ideal moisture content of Oak will differ from Brazilian Cherry just as humidity in Florida will differ from that in Arizona just as the temperature in Winter will differ from that of Summer.

For the majority of oak hardwood floors being installed the ideal moisture content is between 6% to 9%. However, It is always best to check what is appropriate for your specific location as the conditions can vary from region to region.

Wood Flooring Acclimation

The point of acclimating wood flooring before installation it is to allow the moisture content of the wood to adjust to normal living conditions at the installation site.

Once the the hardwood floor is at the jobsite it should acclimate indoors (not in a garage) for 7 to 10 days before the start of installation.

It does no good and is likely harmful to acclimate wood flooring at a jobsite under conditions which do not reflect normal living conditions.

Determining Moisture Content

The most accurate method for determining moisture content is to follow a laboratory procedure where one piece of wood floor is weighed prior to acclimation and then again after. The difference in weight gained or loss represents the Moisture Content of the wood.

However, as it is difficult to bring a laboratory into a home to perform the test it is common for installers to use a moisture meter instead.

Additionally, moisture meters are used to help assess the extent of water damage from leaks or floods.

Ideal Moisture Content for Hardwood Floors

The ideal moisture content for hardwood floors can vary depending upon wood species, geographic location, and the seasonal time of year. For instance, the ideal moisture content of Oak will differ from Brazilian Cherry just as humidity in Florida will differ from that in Arizona just as the temperature in Winter will differ from that of Summer.

For the majority of oak hardwood floors being installed the ideal moisture content is between 6% to 9%. However, It is always best to check what is appropriate for your specific location as the conditions can vary from region to region.

Wood Flooring Acclimation

The point of acclimating wood flooring before installation it is to allow the moisture content of the wood to adjust to normal living conditions at the installation site.

Once the the hardwood floor is at the jobsite it should acclimate indoors (not in a garage) for 7 to 10 days before the start of installation.

It does no good and is likely harmful to acclimate wood flooring at a jobsite under conditions which do not reflect normal living conditions.

Determining Moisture Content

The most accurate method for determining moisture content is to follow a laboratory procedure where one piece of wood floor is weighed prior to acclimation and then again after. The difference in weight gained or loss represents the Moisture Content of the wood.

However, as it is difficult to bring a laboratory into a home to perform the test it is common for installers to use a moisture meter instead.

Additionally, moisture meters are used to help assess the extent of water damage from leaks or floods.

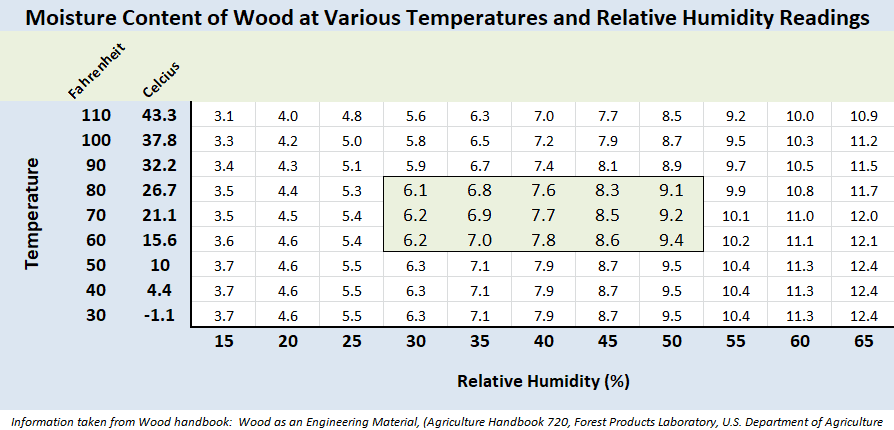

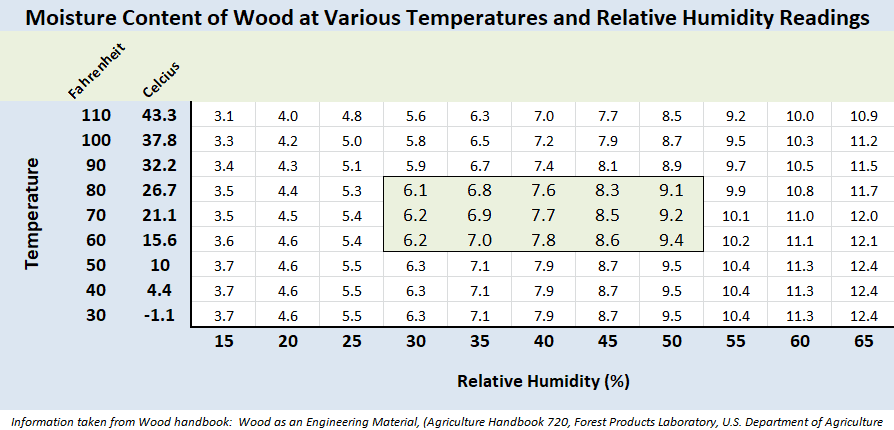

Temperature & Relative Humidity

Wood flooring will perform best when the interior environment is controlled to stay within a relative humidity range of 30-50 percent and a temperature range between 60° to 80° degrees Fahrenheit.

Fortunately, that is about the same range considered to be comfortable for most people.

The chart indicates approximately the moisture content wood will likely have at any given combination of temperature and humidity.

Temperature & Relative Humidity

Wood flooring will perform best when the interior environment is controlled to stay within a relative humidity range of 30-50 percent and a temperature range between 60° to 80° degrees Fahrenheit.

Fortunately, that is about the same range considered to be comfortable for most people.

The chart indicates approximately the moisture content wood will likely have at any given combination of temperature and humidity.

Moisture Related Floor Issues

Some common issues that can occur when wood flooring is not properly acclimated before installation or if the temperature & relative humidity are not within the ideal range are:

Gaps

Narrow gaps will occur naturally due to seasonal changes. Wide gaps are caused when boards were installed with a high moisture content and then subsequently shrink after installed.

Cupping

During the remodel or building of a new home, moisture can enter the house in a number of ways.

Buckling

Boards installed too close together and absorb moisture after installation will raise or pop due to not having room to expand. This is an extreme response to wood with a high moisture content.

Splits/Cracks

Excessive dryness or lack of home humidity can cause the wood to dry out fracturing the cellulose structure of the wood resulting in splits and cracks on the face of the boards.

Time For Delivery

To avoid the above related floor issues make sure before wood is delivered the below projects are completed to minimize the effect of moisture on the hardwood floor.

The building is enclosed and weather-tight, including all doors and windows in place.

All wet trades (drywall, plaster, paint, ceramic tile, etc.) should be completed.

Air conditioning, heating and ventilation have been running for 30 days.

The temperature and relative humidity within the structure are at normal living conditions (i.e. temp 60° to 80° and relative humidity between 30% to 50%).

Time For Delivery

To avoid the above related floor issues make sure before wood is delivered the below projects are completed to minimize the effect of moisture on the hardwood floor.

The building is enclosed and weather-tight, including all doors and windows in place.

All wet trades (drywall, plaster, paint, ceramic tile, etc.) should be completed.

Air conditioning, heating and ventilation have been running for 30 days.

The temperature and relative humidity within the structure are at normal living conditions (i.e. temp 60° to 80° and relative humidity between 30% to 50%).

Share this on: